Before people in the production of noodles to distinguish the degree of thick and thin noodles will be named wide, wide, thin, two fine, imperceptible, chive, etc. .

After having stick noodles, the stick noodles are divided into five basic varieties according to the thickness. Among them, the widest is 6mm, which is called special wide surface or jade belt hanging surface; The width of 3mm is called large broad surface; The width of 2mm is called a small broad surface; The width of 1.5mm is called fine surface; The 1mm thick noodles are called whiskers or silver noodles.

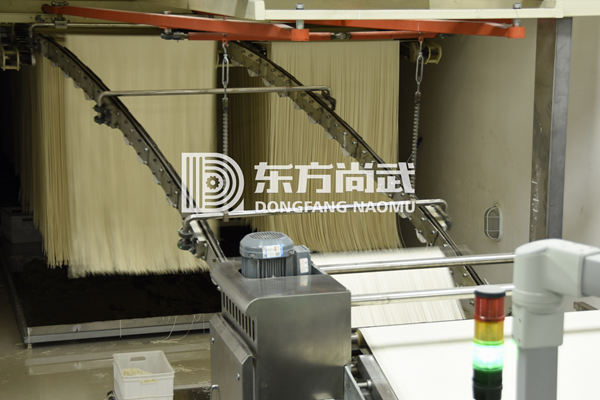

How to solve the problem of noodle thickness unevenness, Zhengzhou Dongfang Naomu Food Machinery Co., Ltd.specializes in producing and selling all kinds of noodle production machinery, automatic stick noodle production line. If there is a difference in the thickness and quality of the dried noodles during the production of the noodle maker, under such a situation, it will certainly be very disadvantageous to the packaging and sales of the dried noodles, because everyone knows that, supermarkets or hypermarkets have requirements on the thickness and specifications of noodle products. In order to sell the noodles normally, it must be necessary to put an end to the occurrence of such a situation, now let's look at how to solve the problem of noodle thickness uneven production noodle?

1. Flour gluten content is less, when produced, there may be thick and thin, and this also affects the toughness and elasticity of noodles.

2. This is also the case when the drying system of the fully-automatic noodle drier goes wrong, because the moisture content of the noodles will affect the shape of the noodles, and the weight of the noodles will increase if the moisture content is high, during the process of noodle hanging rod, excessive stretching occurs, which makes the noodle thickness change.

3. There is a problem with the cutter, which causes the face to deform when pressing, resulting in uneven thickness. Because the cutter is the main component of the wire cutter, if the tooth roller of the tool roller does not mesh deeply enough, there will be drawing, the roller surface is not smooth, cut out the noodles will have burrs, if the surface comb tightness is not enough, face knife groove will accumulate impurities, affect the noodle finish, but also cause the phenomenon of hanging. So we must regularly check, according to the failure reason to make the corresponding maintenance, maintenance.