COMPANY PROFILE

Zhengzhou Dongfang Naomu Food Machinery Co., Ltd.

It has been over forty years since 1975, when the precursor of our company was founded. As a joint venture with our Japanese partner, our company was formed in the year of 2000. In the years from 2002 to 2004, China's national CCTV reported for three consecutive times on the company's research and development of advanced non-fried instant noodle production lines. In 2012, CCTV once again reported on our newly researched automatic stick noodle production lines used in a factory of COFCO. Covering an area of 100 acres, our company has an annual output of a few hundred of production lines. We have a few hundred employees, including 40 engineers, mostly senior engineers, among whom one is an expert recognized by China's State Council.

Devoted to the research and manufacture of instant noodle, stick noodle and non-fried noodle machinery, we have established long-term strategic cooperation with China's large-scale noodle makers, such as Master Kong, Uni-President, Nonshim, Jinshahe, Mingke, Boda, Hualong, etc. Regarding international market, our products have been exported to more than 40 countries, such as Germany, Japan, Russia, Singapore, USA, Indonesia, Vietnam, Myanmar, Cambodia, Nigeria, Philippines, South Africa, as well as the five countries in Middle Asia.

In the principle of “all for customers’ satisfaction”, our company is customer oriented, and has adopted high standards and advanced 5S & CS management strategies in production. Devoted to the research and manufacturing of instant noodle, stick noodle and non-fried noodle machinery, we have established long-term strategic cooperation with China’s large-scale noodle makers, including Master Kong, Uni-President, Nonshim, Baixiang, Guohua, Jinfeng, Jinshahe, Mingke, Boda, Shuangyu, Hualong, Luwang, Ruonan, Jinjian, etc, accounting for 73% market share of China’s food machinery industry. Regarding international market, our products have been exported to more than 40 countries, such as Germany, Japan, Russia, Singapore, USA, Indonesia, Vietnam, Myanmar, Cambodia, Nigeria, Philippines, South Africa, as well as the five countries in Middle Asia.

Adopting advanced technologies from Japan and absorbing international experience, we have created five new advanced, namely: (1)Three-layer compounding; (2)Multi-dimensional stereoscopic rolling <corrugated roller>; (3)Dough aging retaining heat and humidity <dough aging conveyor>; (4)Dough aging retaining heat and humidity for second time <dough belt ripening>; (5)Drying in phases through inner circulation. Our products are advanced, reliable, beautiful, and have reached the top level in China in terms of technology and quality.

SERVICE PROCESS

The company introduces Japanese advanced technology, draws on international successful experience, and innovates five utility model patent technologies

PRODUCT ADVANTAGES

The company introduces Japanese advanced technology, draws on international successful experience, and innovates five utility model patent technologies

R & D STRENGTH

The company occupies more than 600 acres, with an annual output of more than 300 food machines such as noodle production lines and instant noodle equipment, more than 1,000 employees, more than 40 designers and many senior engineers.

With a company-owned technology development department, we can tailor technical engineering solutions according to customer needs.

TECHNICAL TEAM

The company pays attention to the details of the process design, considering comprehensive, attention to detail, professional dedication, and excellence.

The core technical team consists of mechanical design engineers, equipment installation engineers, and production engineers.

HARDWARE FACILITIES

Professional workshop team, combining theory with practice, has rich technical experience.

The production workshop production process is strictly in accordance with the standardization training, and in the process of production, the chief engineer personally guides to ensure the production quality.

INTIMATE SERVICE

Establish standardized operation procedures, project managers to standardize and guide equipment installation, strictly implement the process flow, professional project installation team, perform on-site professional installation and debugging process.

We pay attention to every detail to ensure that nothing is lost.

PLANT EQUIPMENT

More than 300 food machinery such as instant noodle production line and noodle making machine

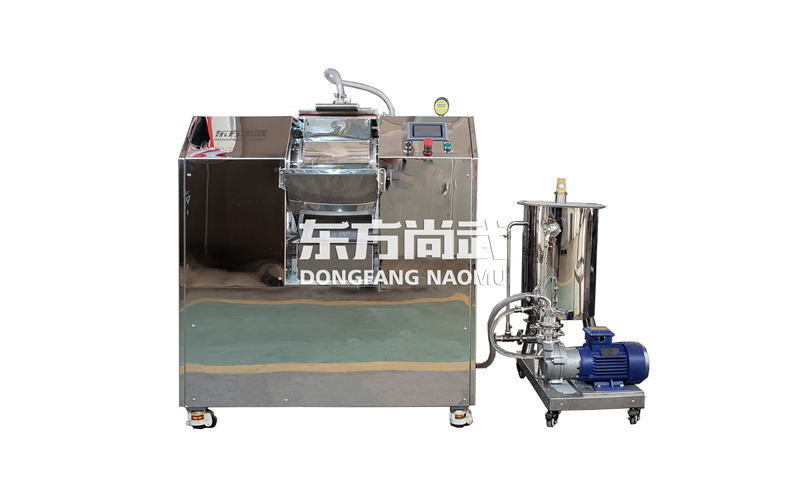

Laboratory Use Noodle Machine

Stick Noodle Production Line Factory

Boiled Udon Noodle Production Line Factory

The Company

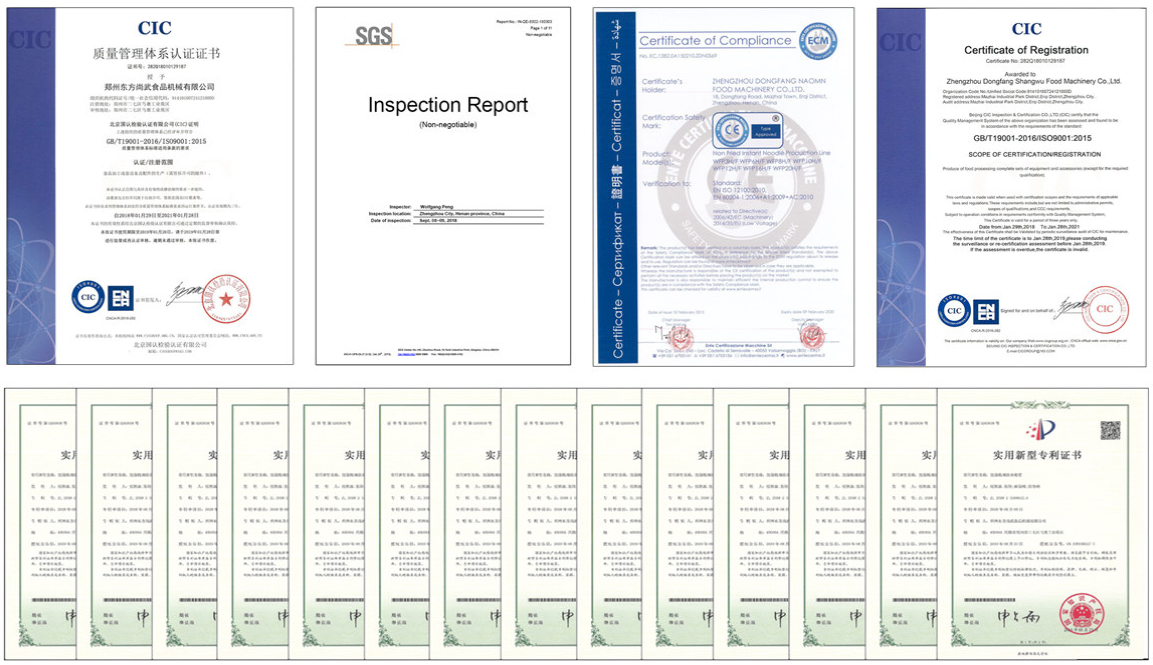

Qualification Honor

Introduce advanced technology from Japan, learn from international successful experience, and declare a number of new practical technologies over the years.

Non-fried Instant Noodle Drying Machine

Qualification Certification

Int'l New-type Big Output Rolling Machine

New-type Multi-layer Steaming Machine

Marketing Network

Decades of production of noodles, instant noodles production line; and exported to Germany, Japan, Russia and other more than 40 countries and regions

In the principle of “all for customers’ satisfaction”, our company is customer oriented, and has adopted high standards and advanced 5S & CS management strategies in production. Devoted to the research and manufacturing of instant noodle, stick noodle and non-fried noodle machinery, we have established long-term strategic cooperation with China’s large-scale noodle makers, including Master Kong, Uni-President, Nonshim, Baixiang, Guohua, Jinfeng, Jinshahe, Mingke, Boda, Shuangyu, Hualong, Luwang, Ruonan, Jinjian, etc, accounting for 73% market share of China’s food machinery industry. Regarding international market, our products have been exported to more than 40 countries, such as Germany, Japan, Russia, Singapore, USA, Indonesia, Vietnam, Myanmar, Cambodia, Nigeria, Philippines, South Africa, as well as the five countries in Middle Asia.

Adopting advanced technologies from Japan and absorbing international experience, we have created five new advanced, namely: (1)Three-layer compounding; (2)Multi-dimensional stereoscopic rolling <corrugated roller>; (3)Dough aging retaining heat and humidity <dough aging conveyor>; (4)Dough aging retaining heat and humidity for second time <dough belt ripening>; (5)Drying in phases through inner circulation. Our products are advanced, reliable, beautiful, and have reached the top level in China in terms of technology and quality.