The Diverse World of Noodle Processing Machinery and Equipment

Classification:

News

Group News

Industry News

Special Reports

Author:

DONGFANG NAOMU

Source:

www.noodlemachinery.com

Release time:

2025-08-16

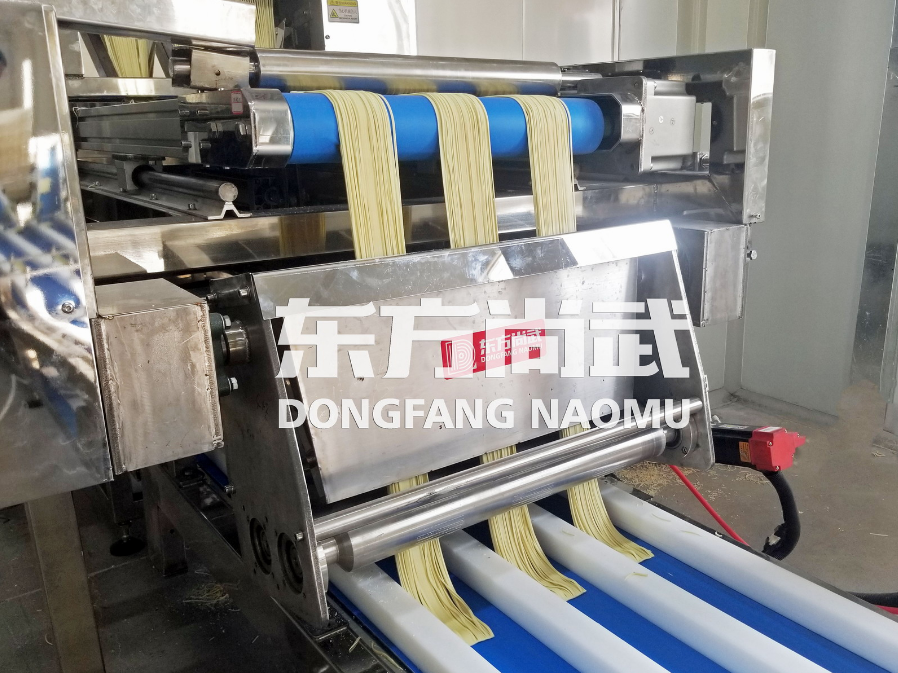

The global noodle industry relies heavily on specialized machinery and equipment designed to produce various types of noodles efficiently and at scale. Noodle processing machinery is categorized into multiple types based on the final product, each requiring distinct technologies and production processes. Among the most common are fresh noodle equipment, stick noodle equipment, instant noodle equipment, semi-dried noodle equipment, and boiled noodle equipment, each serving a unique purpose in the food manufacturing sector.

Fresh noodle equipment is designed to produce noodles with high moisture content, typically consumed shortly after production. These machines handle dough mixing, sheeting, cutting, and packaging while maintaining the soft texture characteristic of fresh noodles. Stick noodle equipment, on the other hand, is optimized for producing long, straight noodles such as those used in traditional Asian dishes. The process involves precise stretching and drying to achieve the desired consistency.

Instant noodle equipment is perhaps the most technologically advanced, incorporating frying or air-drying stages to create shelf-stable products. These production lines are highly automated, featuring mixing, steaming, frying, and seasoning systems to meet mass-market demands. Semi-dried noodle equipment strikes a balance between fresh and dried noodles, offering a longer shelf life than fresh noodles while retaining a softer texture compared to fully dried varieties.

Boiled noodle equipment is specialized for par-cooked noodles, which are partially boiled before packaging to reduce preparation time for consumers. This type of machinery often includes blanching and quick-cooling systems to ensure food safety and quality.

As consumer preferences evolve, noodle processing machinery continues to innovate, integrating smart technologies for better automation, energy efficiency, and hygiene standards. Companies like Zhengzhou Dongfang Naomu Food Machinery Co., Ltd. contribute to this industry by developing advanced solutions that enhance production efficiency and product consistency. The diversity in equipment ensures that manufacturers can meet global demand for all noodle varieties, from artisanal fresh noodles to mass-produced instant meals. This dynamic sector remains a cornerstone of the food processing industry, adapting to new trends while maintaining the traditions of noodle-making.