Key Components of Round Instant Noodles Stretching & Soaking Device

Classification:

News

Group News

Industry News

Special Reports

Author:

DONGFANG NAOMU

Source:

www.noodlemachinery.com

Release time:

2025-05-24

In the modern food processing industry, the production of round instant noodles has become a highly automated and efficient process. One of the key components in this production line is the stretching and soaking device, which plays a crucial role in ensuring the quality and consistency of the final product. This device is a complex assembly of various components, each contributing to the overall functionality and efficiency of the process.

At the heart of the stretching and soaking device is the circulating pump. This pump is responsible for maintaining a continuous flow of water or other soaking solutions through the system. It ensures that the noodles are evenly soaked, which is essential for achieving the desired texture and consistency. The pump's reliability and efficiency are critical, as any interruption in the flow can lead to uneven soaking and, ultimately, a lower quality product.

The secondary stretching device is another vital component of this assembly. It is designed to apply additional tension to the noodles after the initial stretching process. This step helps to further refine the shape and texture of the noodles, making them more uniform and suitable for the final drying and packaging stages. The precision of the stretching process is crucial, as it directly impacts the appearance and mouthfeel of the noodles.

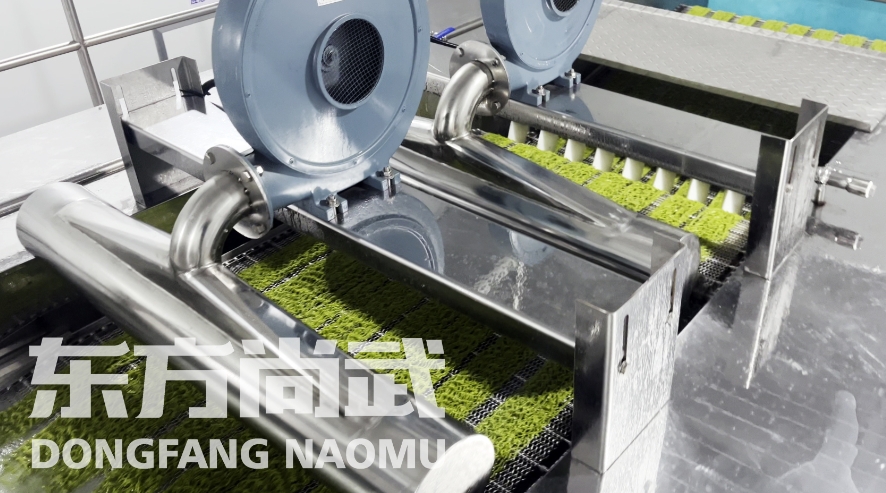

An integral part of the stretching and soaking device is the air knife. This component is used to remove excess water from the noodles after soaking. The air knife uses a high-velocity stream of air to blow off the excess moisture, ensuring that the noodles are not overly wet when they move to the next stage of production. This step is important for maintaining the structural integrity of the noodles and preventing them from sticking together.

The axial flow fan is another essential element in this system. It provides a steady flow of air that helps to dry the noodles further after the air knife has removed the excess moisture. The fan's airflow is carefully controlled to ensure that the noodles are dried evenly without being damaged. Proper drying is crucial for the preservation and shelf life of the instant noodles.

The waterfall spray is a unique feature of the stretching and soaking device. It is designed to distribute the soaking solution evenly over the noodles. The spray creates a cascading effect that ensures every noodle is thoroughly soaked. This uniform soaking is essential for achieving a consistent texture throughout the batch of noodles.

Finally, the entire assembly is supported by a sturdy frame. This frame not only holds all the components together but also ensures that the device is stable and secure during operation. The design of the frame allows for easy maintenance and access to all the components, which is important for keeping the production line running smoothly.

At Zhengzhou Dongfang Naomu Food Machinery Co., Ltd., the importance of each component in the stretching and soaking device is well understood. The company's commitment to innovation and quality ensures that their production lines are equipped with the most efficient and reliable systems. By focusing on the details of each component, from the circulating pump to the waterfall spray, Zhengzhou Dongfang Naomu Food Machinery Co., Ltd. ensures that their instant noodles meet the highest standards of quality and consistency.