In the production process of stick noodle production line equipment, it is inevitable to produce broken noodle. The amount of broken heads in noodle generally accounts for about 10% to 15% of the feeding amount, which cannot be ignored. These broken heads need to be dealt with in a timely manner before processing. Moreover, the quality of the broken head treatment is crucial for the economic benefits of noodle production.

The treatment method for dry broken noodle of stick noodles: Usually, the broken noodle that fall after the drying room, that is, the noodles in the cutting or packaging section, are called dry broken noodle. The moisture content of the dry crushed dough is similar to that of the finished dough, but its properties are completely different from flour. Therefore, it needs to be professionally processed before being mixed into the dough mixer and thoroughly stirred.

There are usually two methods: wet treatment and dry treatment. Wet treatment: It involves soaking the cleaned dried broken noodle of stick noodles, allowing them to fully absorb water and soften, and then mixing them with flour in a certain proportion in a dough mixer. The main reason is that the degree of damage to the gluten network organization in the broken head is small, which has little impact on the process and product quality. However, the disadvantage is that the soaking time needs to be controlled well, especially in summer when it is prone to sourness and deterioration. Also, keep the soaking pool clean and hygienic. However, dry processing overcomes the shortcomings of wet processing, solves hygiene issues, and has low labor intensity. It only needs to crush the coarse powder of the crushed dough to the required fineness. But it is necessary to strictly control the proportion of flour powder added.

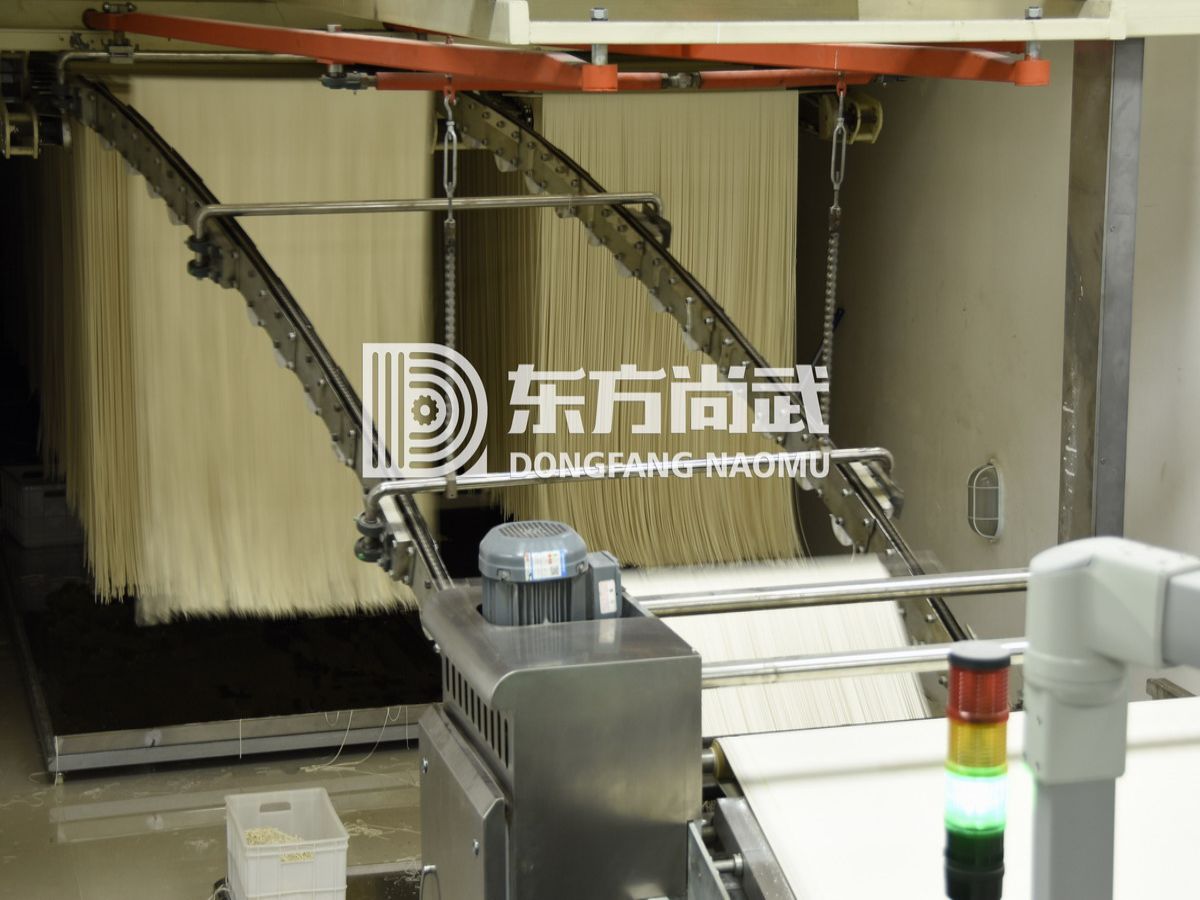

We, Dongfang Naomu Machinery Equipment Co., Ltd., have been specializing in the manufacturing of stick noodle machines and stick noodle production lines for over 40 years. Our noodle production lines are equipped with wet noodle recycling and dry noodle crushing systems. The wet noodle recycling system uses food grade non-toxic belt conveyor, organic glass cover plate, and aluminum alloy frame, which automatically recycles waste materials and sends them to the noodle machine during continuous startup. The dry noodle crushing system is equipped with one coarse crushing and grinding machine, and one fine crushing and grinding machine. It can crush and transport the cutting blade surface head to the grinding machine, and grind it to the required particle size (>40 mesh) for easy reuse.